Echipamente de Laborator pentru Tehnologia Amestecarii

BUN VENIT LA ASCOMEX

ASCOMEX reprezintă în România producători de vârf din Uniunea Europeană care oferă soluții tehnice avansate în domeniul realizării de amestecuri de: lichid cu lichid, lichid cu solid, solid cu solid ( pulberi ), micșorarea de particule lichide, dizolvări, realizarea de dispersii, emulsii, omogenizări, spălări cu distilare de solvenți, spălări – igienizări la locul de producție, măcinări, aparatură de laborator. Industriile cărora ASCOMEX se adresează pentru oferta de echipamente destinate aplicațiilor menționate sunt: industria farmaceutică, industria cosmetică, industria alimentară, industria chimică și petrochimică, biotehnologie. Producătorii reprezentați de către ASCOMEX oferă soluții industriale complexe, pornind de la designul unor echipamente și instalații complexe, până la servicii după-vanzare.

PARTENERII NOSTRI

Echipamentele industriale sunt oferite de la producatori europeni de varf din Danemarca, Germania, Elvetia si Belgia, a caror reprezentanta exclusiva o avem pe piata din Romania.

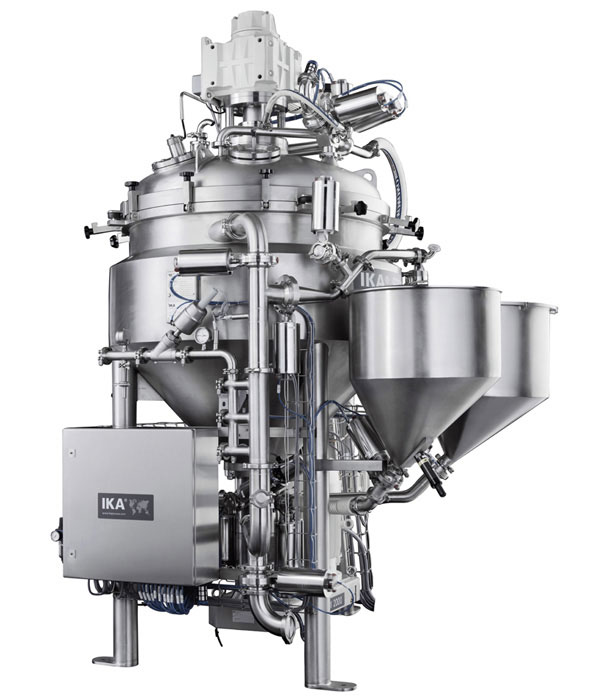

IKA

D.W. RENZMANN

Willy A. Bachofen

JEHMLICH

DIAF PILVAD

ECHIPAMENTE DE LABORATOR

Echipamentele de laborator sunt oferite de producatorul european de varf IKA Germania, a carui reprezentanta exclusiva o avem pe piata din Romania.

APLICATII

- Industria farmaceutica

- Cercetare stiintifica

- Biotehnologie

- Industria cosmeticelor

ECHIPAMENTE SI UTILAJE INDUSTRIALE

Echipamentele industriale sunt oferite de la producatori europeni de varf din Danemarca, Germania, Elvetia si Belgia, a caror reprezentanta exclusiva o avem pe piata din Romania.

PRODUSE

- Machines for coarse milling and crushing.

- Rekord impact mills.

- Customized fine grinding plants.

- Innovative dozing technology.

- Testing facility.

- And much more…

APPLICATIONS

- Food industry.

- Beverage industry.

- Pharmaceutical industry.

- Cosmetic industry.